Patented Heating Wire

ZL 2016 2 0798237.3

We select the highest quality materials and strictly control every aspect of heating wire production.

About Our Heating Wire Production

In order to ensure the production of heating elements that can withstand high temperatures, heat evenly, have a long service life, and are safe and reliable. We select the highest quality materials and strictly control every aspect of heating wire production.

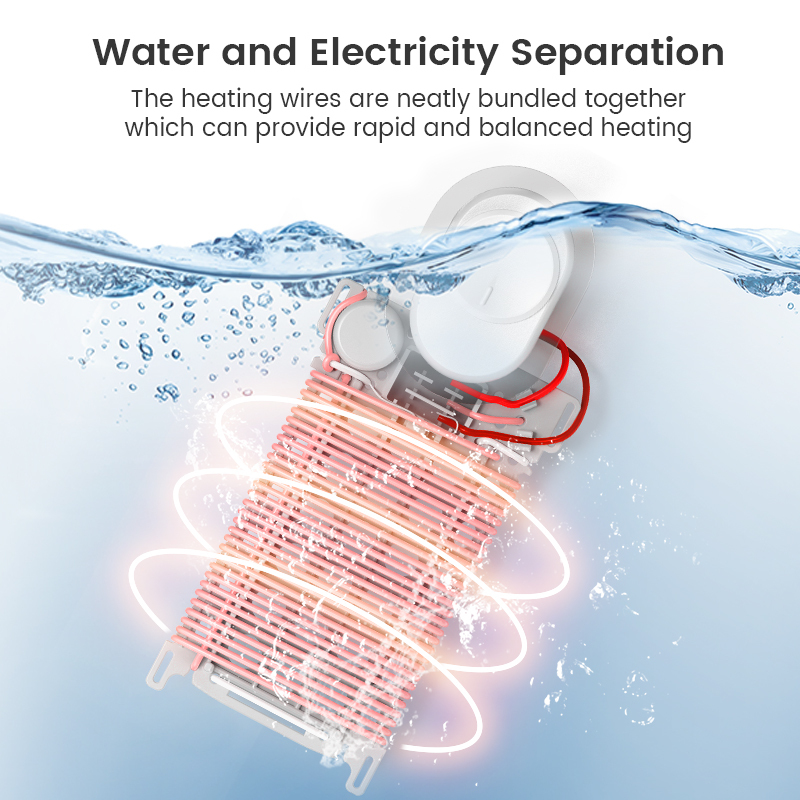

1. Preparation Of Heating Wire

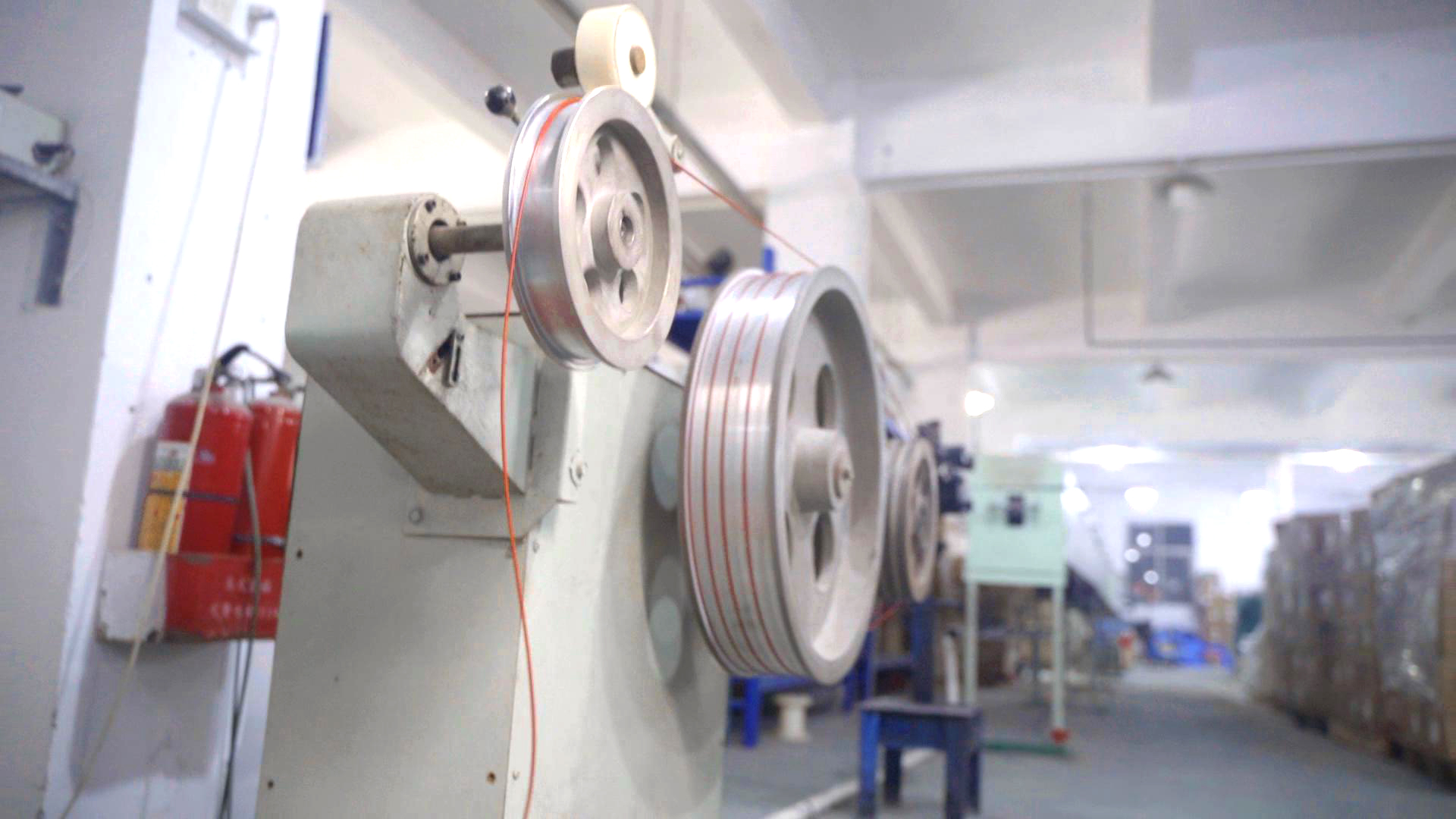

We choose nickel-chromium alloy wire with good high temperature resistance and electrical conductivity as the material of the heating wire. First, the selected nickel-chromium alloy wire is processed by processes such as drawing and straightening to turn it into a thin wire form.

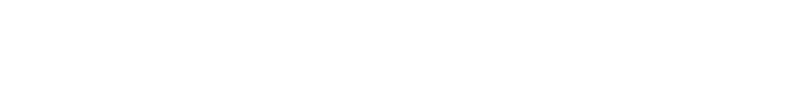

2. Silicone Coating

The heating wire passes through a mechanical device to evenly pass through the mixture containing silica gel, so that the silica gel is coated on the heating wire. We will adjust the process according to specific needs to ensure the uniformity of the silicone-coated heating wire.

3. Silicone Curing

The heating wire coated with silicone is baked through a curing process or the silicone is cured in a constant temperature oven. During the curing process, the silicone reacts chemically, hardening it and forming a protective layer that covers the heating wire. This process enhances the high-temperature resistance of the heating wire and ensures the adhesion between the insulation layer and the heating wire.

4. Silicone Coating And Trimming

The cured silicone heating wire continues to be further trimmed with mechanical tools to ensure that the diameter and shape of the heating wire are within the specified range to ensure that it can be heated evenly and have good electrical conductivity.

5.Quality Inspection

The prepared silicone heating wire is cooled for a period of time, and conduct a quality inspection on the heating wire to verify whether its performance and function are within the specified range.

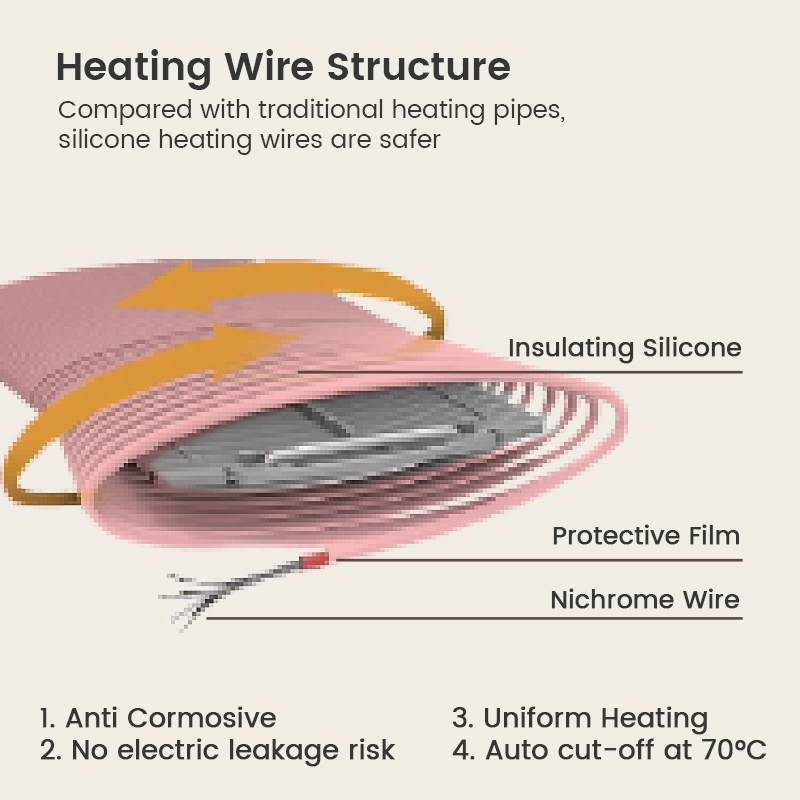

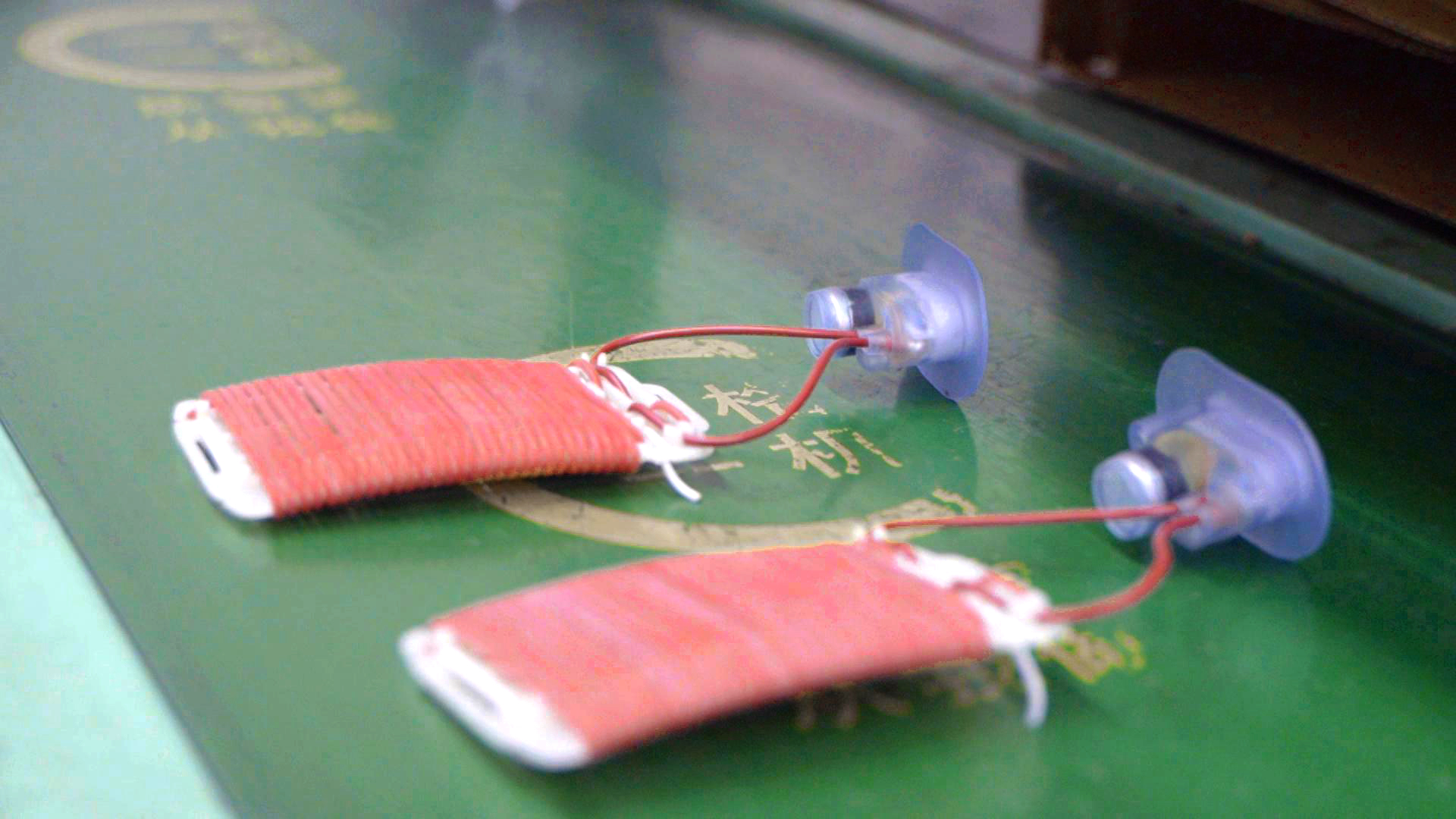

6. Make Heating Wire Components

Cut the heating wire to the required length, neatly wrap it around the nylon fiber-reinforced board and connect it to other components to create a complete heating structure.