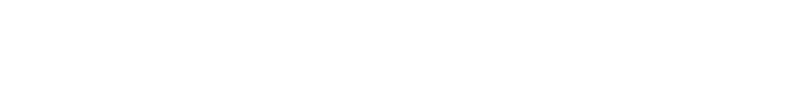

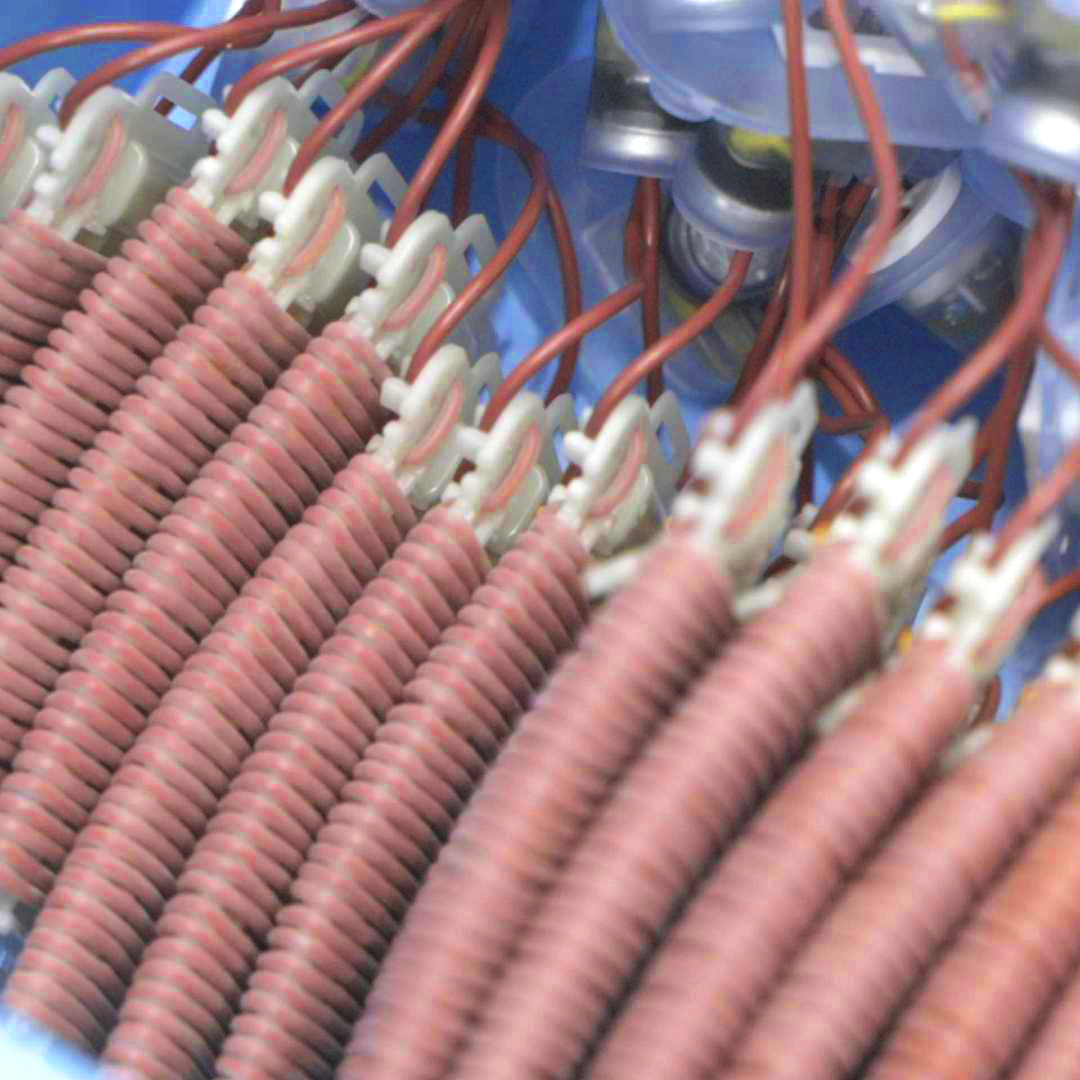

We use a voltage value higher than the normal working voltage to conduct a high-voltage test on the heating head, and at the same time check whether the red indicator light is on. This step is designed to check whether the current output of the heating head under high voltage meets the design and standard requirements to ensure that the equipment can work normally under high voltage conditions and will not cause dangerous situations such as leakage and short circuit.

MORE

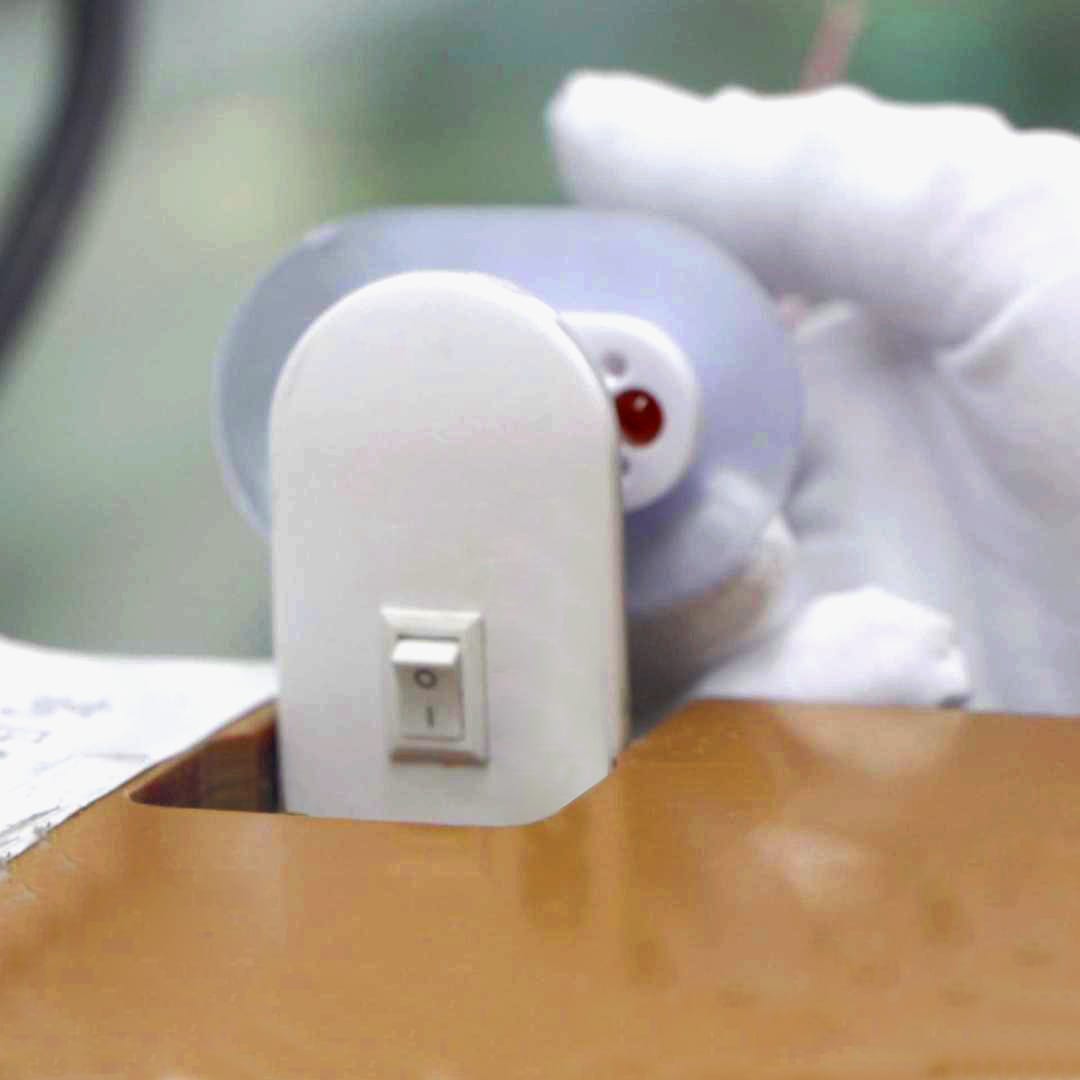

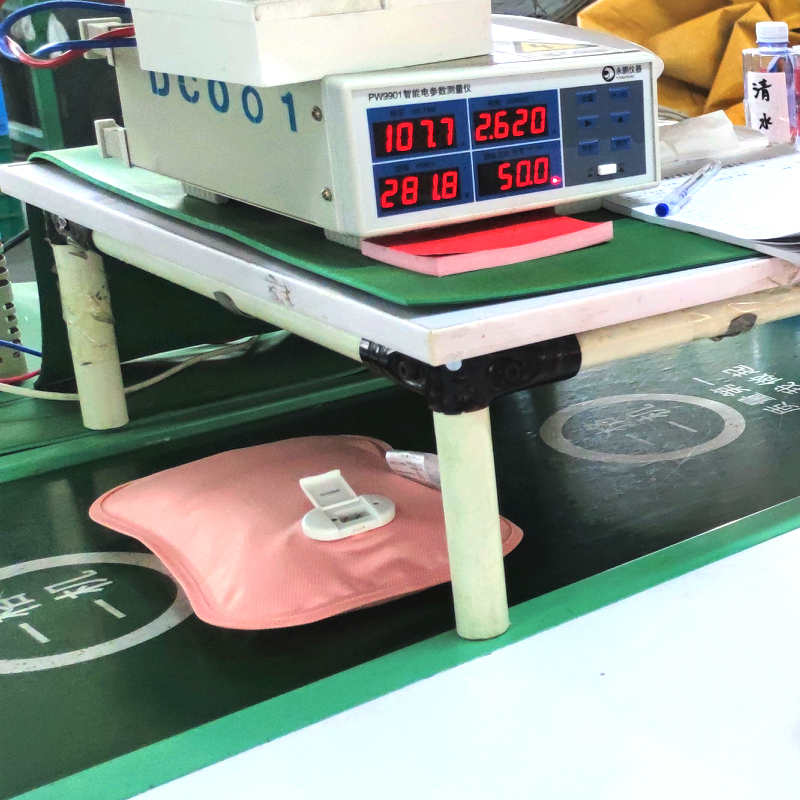

After testing the electric heating head, the current and power of the entire heating structure will be measured to check whether the working condition of the entire heating structure is stable and ensure that there is no obvious change before and after the high-voltage test to ensure the working performance and safety of the equipment.

MORE

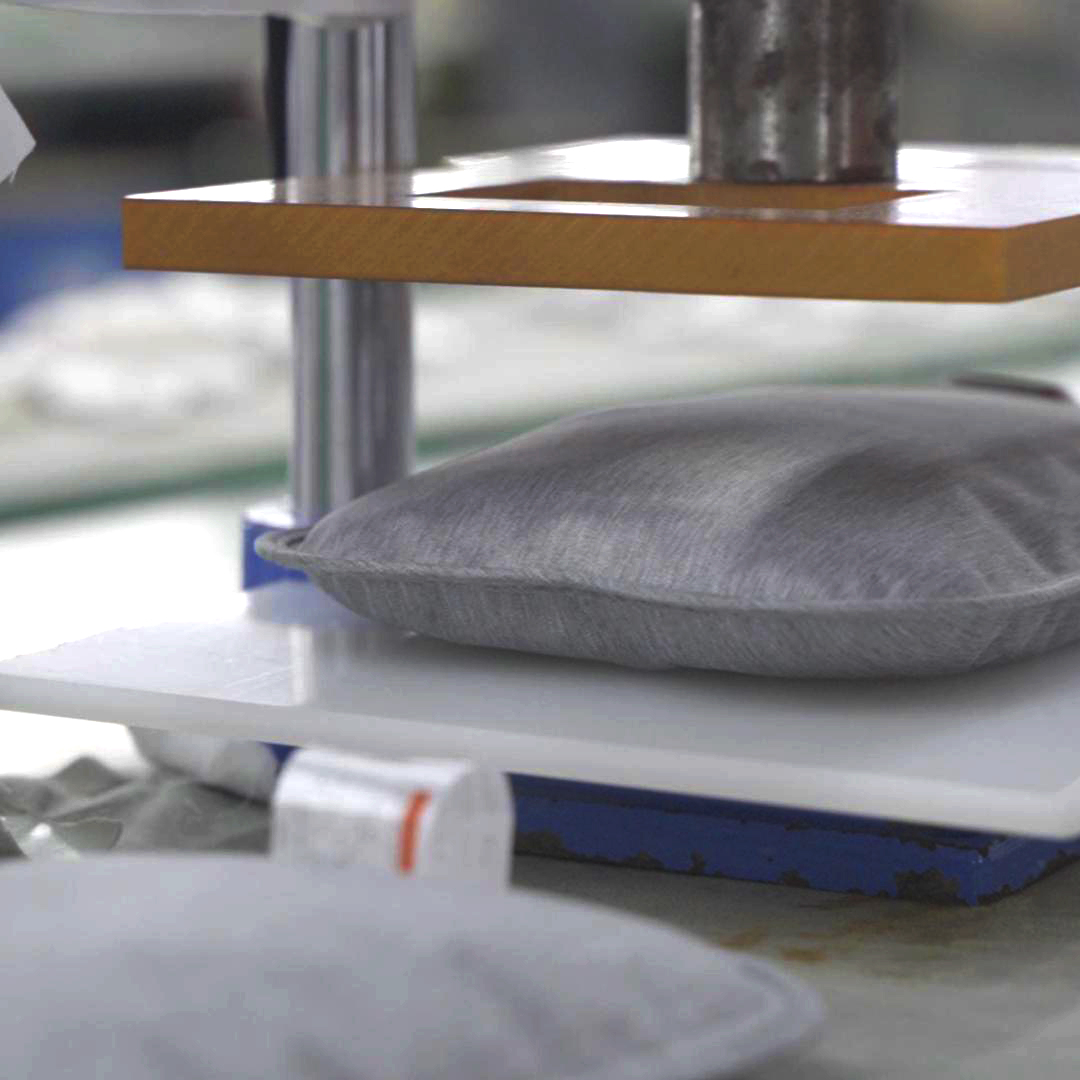

Place the hot water bottle flatly on the fixture table, turn on the switch, press the pressure to 80-100, press the cylinder downward, and press the flat plate on the surface of the hot water bottle for 5 seconds (the specific pressure and time are strictly implemented according to customer requirements), and the cylinder will automatically retract . Take out the pressure-tested hot water bottle and check for leaks around it.

MORE

1. Check whether the voltage and power of the hot water bottle are within the specified range

2. Take the hot water bottle and check whether there is any appearance defect

3. Plug the charging clip into the power supply and observe whether the parameters are within the normal range.

Test whether the electric hot water bottle can maintain normal function after long-term use. The electric hot water bottle is placed in a constant temperature environment for several consecutive days to perform cycle charge and discharge tests to simulate the lifespan under actual usage conditions. According to data analysis, the general service life of our electric hot water bottles is about 3 years.

MORE

We conduct random inspections of 15%-20% of the goods to be sent out. Through visual inspection, touch and machine inspection, every detail of the hot water bottle is comprehensively inspected to ensure that various parameters comply with the specified range and meet customer quality requirements.

MORE

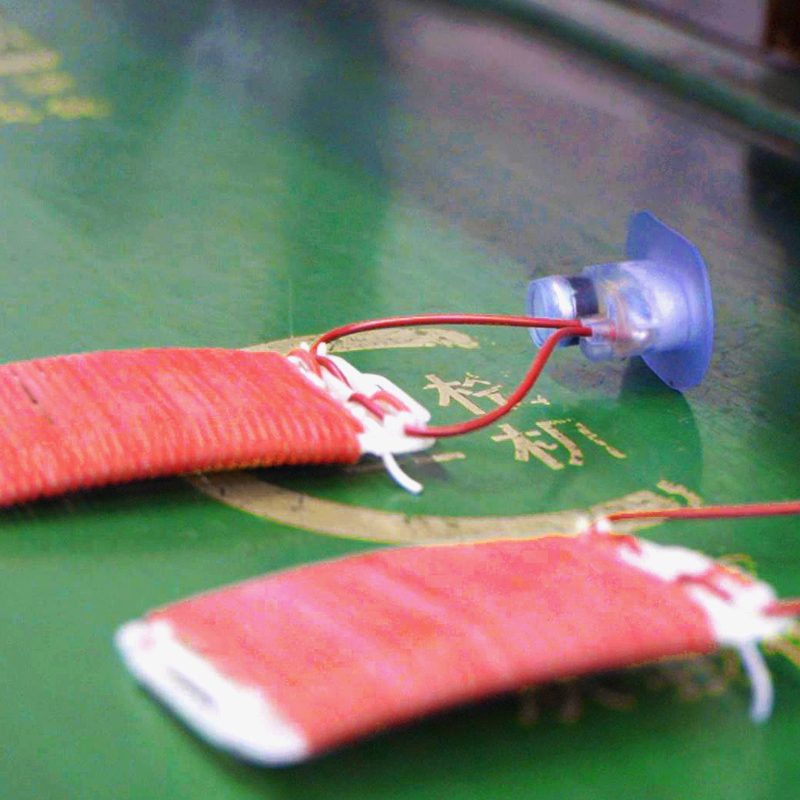

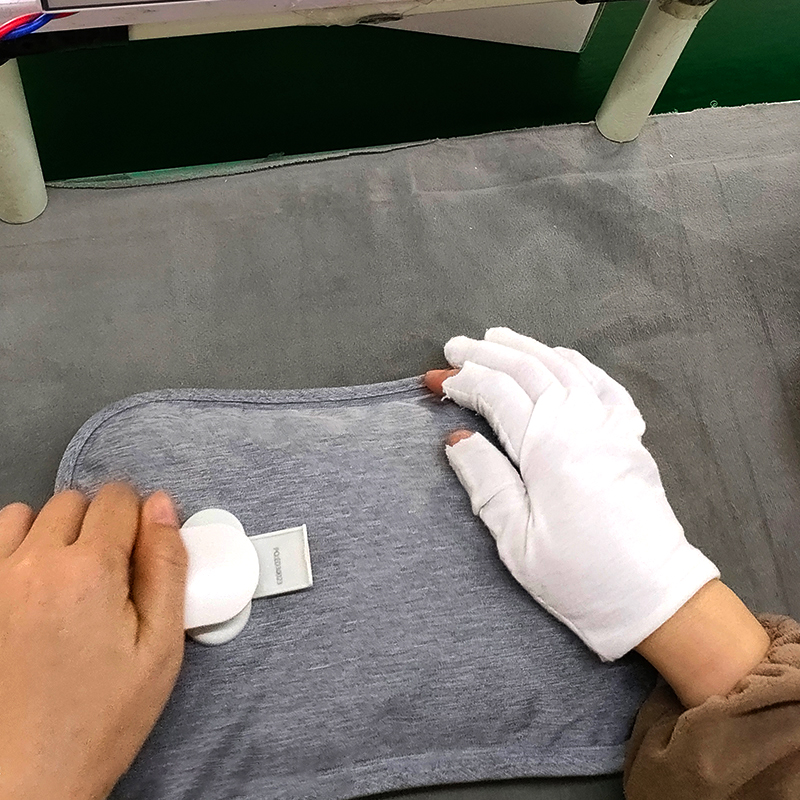

By detecting whether there are broken metal needles in the cloth cover, the safety and quality of the product can be ensured. We use high-precision needle inspection tools for inspection. If a metal needle is found to be broken, replace or repair the cloth cover immediately to ensure user safety.

MORE